Organic fertilizers are those with plant or animal origins. Organic fertilizers have lower percentage of nutrients, in comparison with mineral or chemical ones, but usually provide acceptable amounts of nutritional requirements for trees. In addition to main elements (N, P, and K), organic fertilizers consist of micro elements (Ferrous, Zinc, Copper…). Nowadays, mass residue of traditional and industrial poultry farms is a serious problem for their owners and they are very willing to sell the residue to organic fertilizer producing plants. Accumulation of these materials gradually leads to severe pollution of air, soil and water. Enriched organic fertilizers have numerous advantages as below:

1) They can be replaced by mineral fertilizers to a high extent and as mineral fertilizers have high prices, utilizing organic fertilizers reduces the costs.

2) In these fertilizers it is possible to change the percentage of macro and micro elements arbitrarily. In other words, based on nutritional requirements of various areas, different formulas (containing desired percentages of macro and micro elements) can be produced.

3) In accordance with soil and water conditions, it is possible to add useful biological materials, like bacteria (Thiobacillus), fungi and useful microorganisms, to these types of fertilizers to improve soil characteristics and optimum absorption.

4) In contrast to most of the chemical fertilizers, the organic ones have more sustainability in soil and sometimes can be effective up to 2 to 3 years.

Nowadays, compost is described as a substitute for chemical fertilizers which have disadvantages for human health and also for agricultural fields. However, there are some problems in providing this kind of fertilizer for farms, like transportation (in big volumes), high moisture, distribution in farm, dust and storage. Pelleting and granulation, as compression solutions, are proposed to solve these problems.

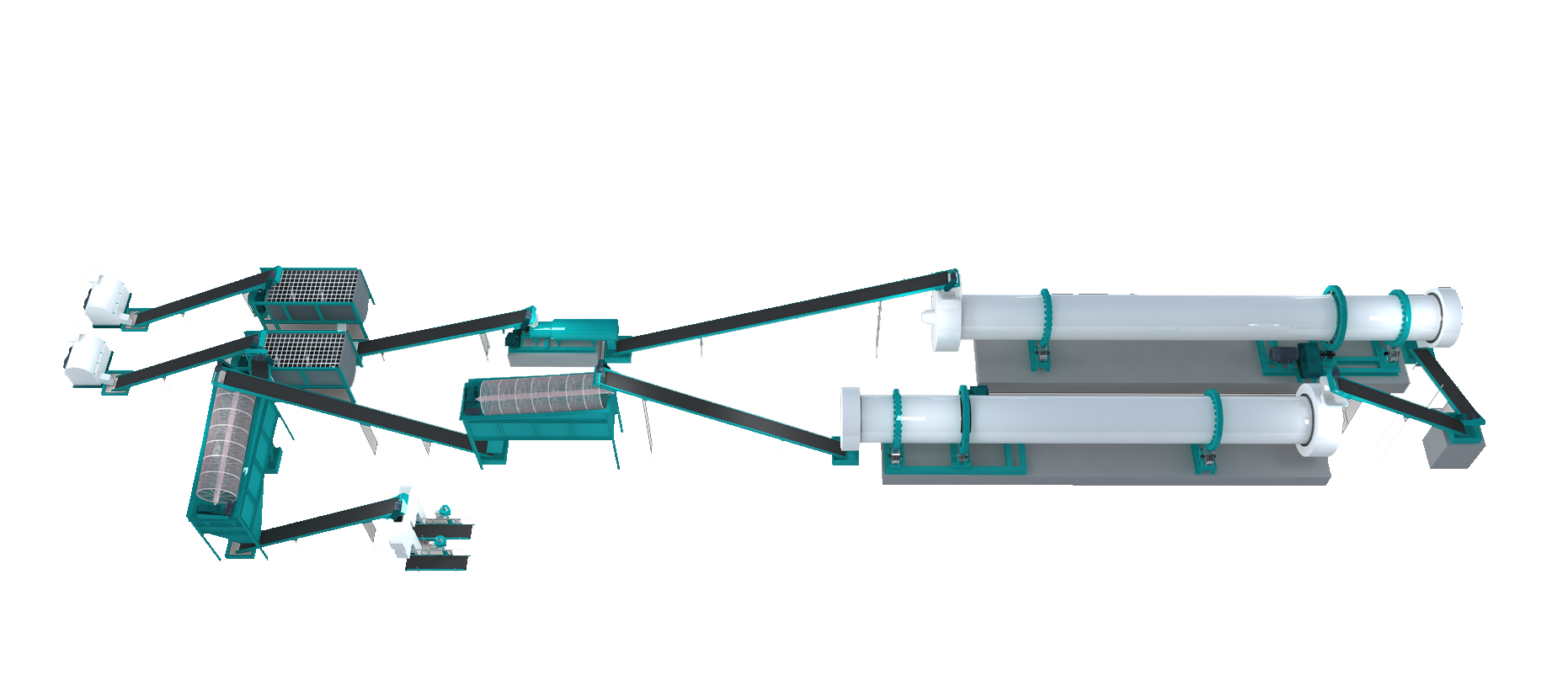

When raw materials are changed to compost, fertilizers are provided in special shapes package, based on the consumption market. So, it is essential to utilize granular or pellet production line in order to transform fertilizer into granules or pellets.

Usually three shapes of fertilizers are used throughout the world:

a) Powder fertilizers

b) Granular fertilizers

c) Pellet fertilizers

Powder Fertilizers

In order to produce this kind of fertilizer, raw materials are grinded and combined in definite proportions and then are mixed and packed in different packages based on the consumption market.

Granular Fertilizers

This type of fertilizer is circular (like a ball) and is popular among consumers due to its easy application in agricultural and horticultural sections. It is also possible to distribute these fertilizers in farms by spreaders and seeders. In order to produce granular fertilizer, its production line is required.

Pellet Fertilizers

This type of fertilizer is in cylindrical (tubular) shape. Material compression of pellet fertilizers is more than granular ones and in Iran, gardeners use more of this type of fertilizers.

Specifications of granular or pellet fertilizer processing lines:

1) Transforming compost into granulated or granular fertilizers

2) Possibility of fertilizer enrichment with additives required in an area

3) Mechanized processing of compost to granular fertilizer packages

4) Low investment costs

5) Outstanding added value for compost due to price difference with granular fertilizers

6) After-sales services and supply of spare parts