all Products

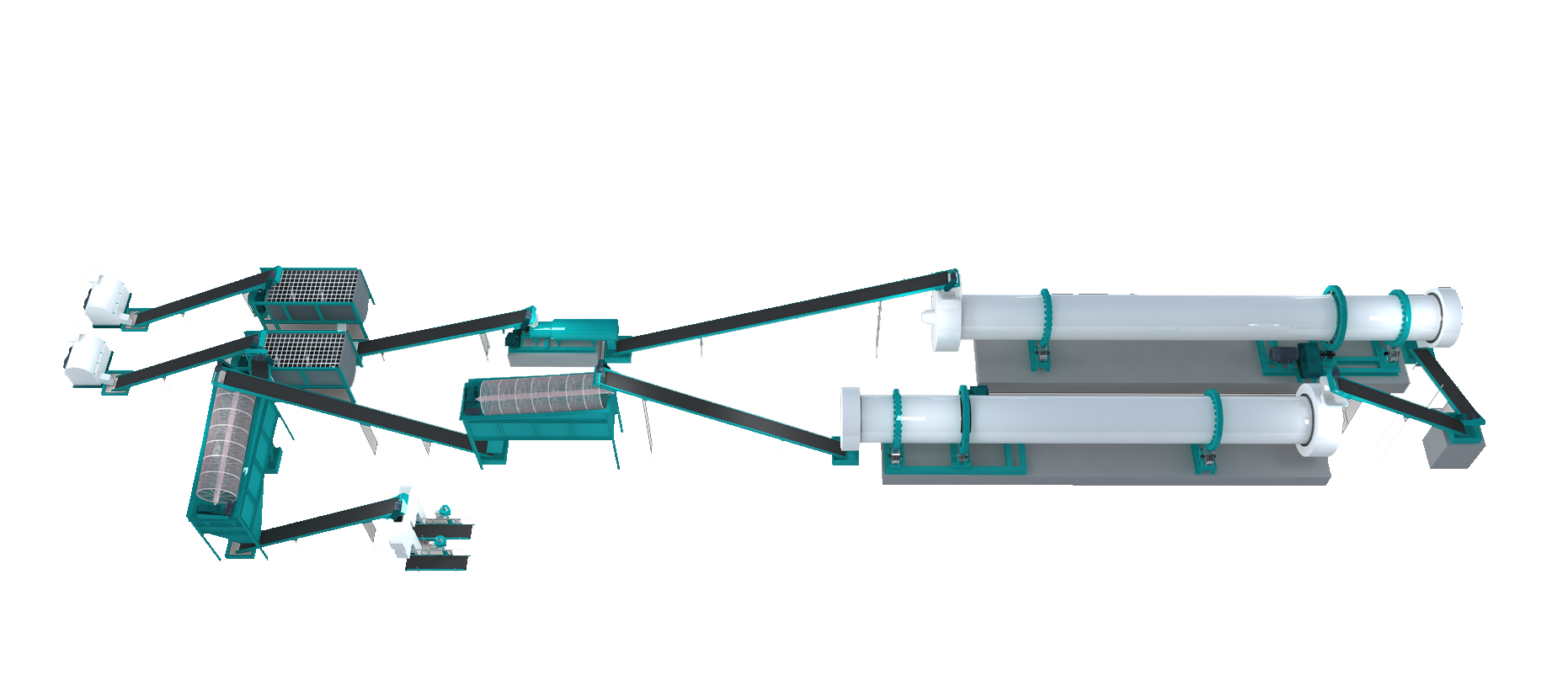

Biogas Plants

During the history of mankind, human’s relationship with the environment has always been following his behavior with his natural surroundings. Advances in technology and its non-compliance with the environment, changes in human civilizations in different eras, and ignoring the right relations between human needs and the environment has faced the lives of all beings on earth with more complicated issues.

Increasing global population and the high dependence of human kind on energy to do daily activities raises the demand for energy. On the other hand, rapid decrease of common energy sources across the world, pollution resulting of the consumption of fossil fuels, production of great volume of pollutants and wastes and lack of management and supervision of their disposal has become a new problem for people.

Nowadays, utilization of biogas technology in macro and micro scales, as a prospering approach in organic waste development and management plans in urban and rural areas is of great concern. Biogas, as a source of renewable energy, has significant social and economic interests and has an outstanding role in solving environmental problems resulting from pollutants and organic wastes in human societies. One of the problems dairy farmers are involved with, is to control livestock waste to decrease the annoying smell and other remnants causing environmental problems.

Biogas can help us to overcome the afore-mentioned problems and its environmental benefits include control of the annoying smell, improvement of air and water quality, improvement of nutritional value of the output manure, decrease of green gas emissions, and having biogas as a source of energy. Utilization of biogas has attracted a lot of attention in heat and power plants to produce energy, due to its economic, social and environmental benefits. Producing biogas by anaerobic digestion and its application in CHP plants in Iran can help the country to not only supply a part of required energy, but also enable the nation to step into a stable development stage.

Biogas installations can be used for different applications, as below:

– Waste sludge in waste water treatment plants

– Livestock and poultry wastes, including manure, feed and agricultural wastes

– Organic materials of civil wastes

– Wastes from slaughterhouses

– …

Biogas can be converted into following forms of energy, under special procedures:

Electricity: Biogas can be converted to electricity to be used in the network, by combusting process in CHP

Heat: In addition to generation of electricity in CHP, produced heat has also vast applications in industries and residential areas.

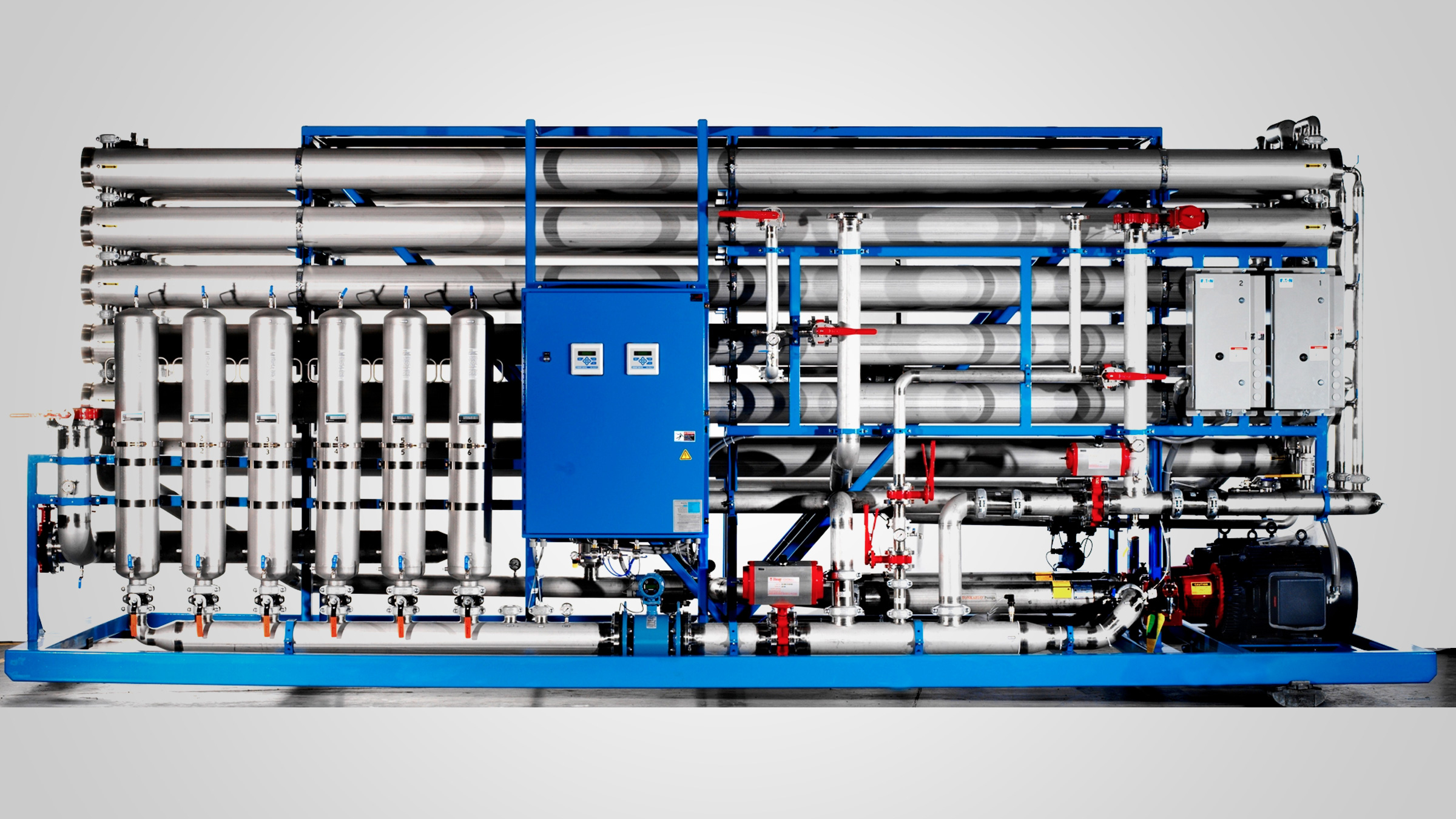

Methane: Methane can be converted to a high-quality natural gas to be inserted in the gas distribution network by applying special methods.

In addition to power and heat generation, biogas can be inserted into the local gas distribution network as natural gas, which is a futuristic and beneficial approach toward a source of energy, compatible with the natural environment. The other by-product of biogas is the valuable manure produced in the plant, to be sold out and used in the agricultural section.

Biomethane refinery requires a high technology in terms of installations. High level of automation, precise control systems for installations to control the production process and remote maintenance methods are vital in these plants. Moreover, compliance to environmental conditions of where the plant is going to be installed is of great importance.

Followings are some of the unique features of installations:

– Long life span

– Special designing and manufacturing, based on the contractor’s condition

– Appropriate process for all kinds of organic materials

– High performance installations with the lowest maintenance and repair costs

– High quality technology

– Production of electricity, heat and manure